MS-LON1 for Microsoft in Germany

We had the chance to take on the Project of MS-LON1 for Microsoft in Germany. And this one wasn’t our average day in the world of Piping Engineering Services.

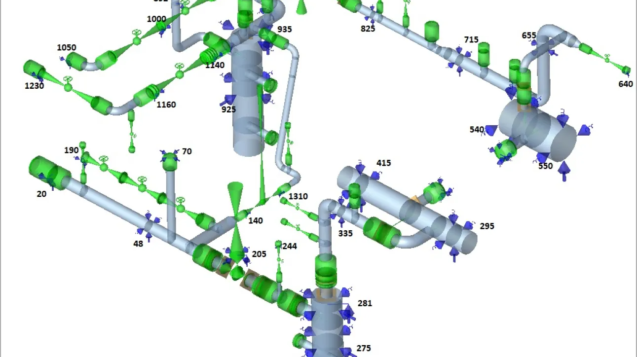

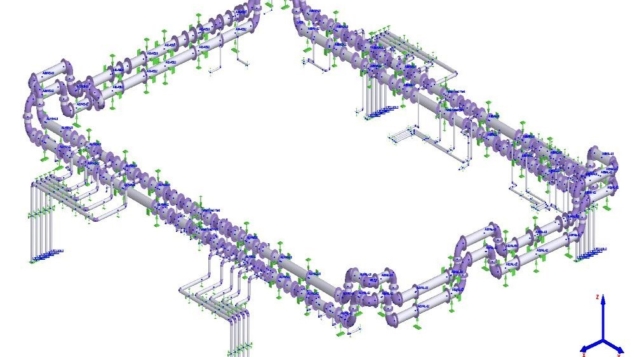

When we got the call to handle pipe stress analysis for their chilled water (CHW) systems, we knew it would be big. Not just in terms of the client — we mean, it’s Microsoft, right? — but also the scope. We’re talking piping sizes up to 1000DN. That’s some serious diameter to deal with.

The Role We Played

The Role We Played: Lead Pipe Stress Analyst

Keeping It Flexible (And Cost-Friendly)

Keeping It Flexible

Our role was to lead the pipe stress analysis, making sure the CHW piping system could take the heat, or well, the cold, without causing any surprises down the line. At Fluxiss, we’ve handled plenty of complex jobs before, but every project brings something new to the table. And that’s what keeps things interesting.

The challenge here? To develop an expansion strategy that wouldn’t ask the design team to go back to the drawing board. That’s where real-world Piping Engineering Solutions come in handy.

Keeping It Flexible (And Cost-Friendly)

Redesigns can be painful — they take a lot of time, are expensive and can usually be avoided. So, rather than loading our games with tons of extra features, we picked a more flexible design for pipes in the game.

Looking closely at the routing and moving pieces around helped the system expand without problems. Only one level of action occurs. Just basic tools needed. All we need is the right knowledge and history of working in Piping Engineering Services.

This method pleased the client (by reducing costs) and helped them avoid any delays. That’s always a good result for all involved.

Friction Factors? We Dug Deeper

This may sound basic, but friction factors really made a strong difference in the equation. We performed thorough checkups on friction values in different products, allowing Microsoft to see clearly what the effects would be on long-term system performance.

The challenge here? To develop an expansion strategy that wouldn’t ask the design team to go back to the drawing board. That’s where real-world Piping Engineering Solutions come in handy.