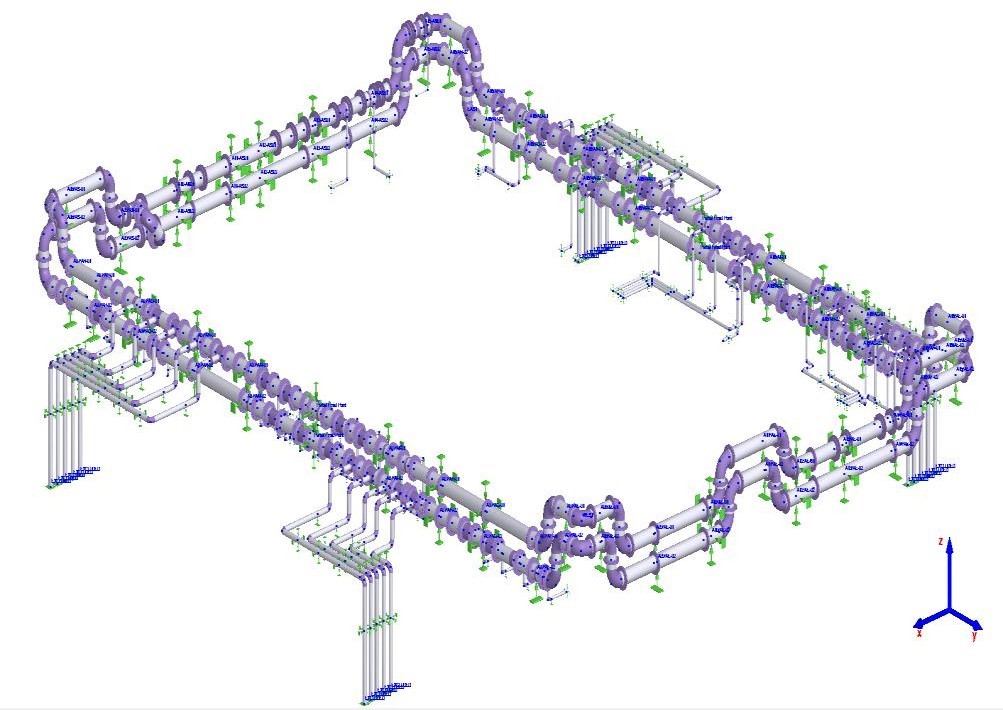

Service: Pipe stress analysis – Hot water/Industrial pipelines

Fluxiss was in partnership with Parlym, a French engineering company, carried out a comprehensive stress analysis of the hot water piping work of an industrial plant. The project involved one of the most sensitive systems, where temperature adjustment was a dreadful issue bound to cause problems to the system– and that is where our prowess came through.

Our Approach – Real Engineering, Not Just Simulation

We begin by going through the isometrics and line list supplied by the client. And by no over-complication — go right into the real stuff. We overlaid thermal expansion, long-term loads, and operating pressures into well-crafted load cases. Expansion is a major design limitation with hot water pipelines; hence, we made critical attention in the analysis of flexibility.

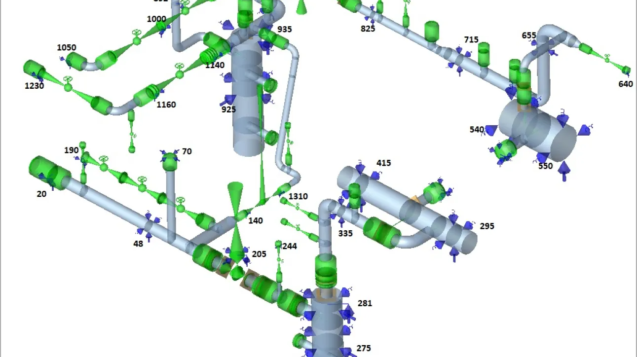

Using ASME B31.3 as the reference code, we ran a series of load combinations and made adjustments to support locations, guide spacing, and anchor placement — all to optimize load distribution and reduce stress at sensitive points, especially near equipment nozzles.

Beyond Software – Hands-On Stress Engineering

Our engineers manually verified critical areas after modeling to ensure actual on-site feasibility. Every movement, every load — checked, reviewed, and backed with logic. That’s what separates routine analysis from practical pipe stress engineering.

At Fluxiss, we don’t do pipe stress analysis just to tick a box — we do it to make sure the piping works where it counts: in the real world.