Working with SITES S.r.l. – Italy was one of those projects that reminded us why we do what we do at Fluxiss. When you get a chance to collaborate with a company that’s been around since 1989 and evolved so gracefully from basic electrical installations to full-blown industrial plant systems, you know it’s not just business, it’s a learning journey too.

Delivering the Right Pipe Engineering Solution

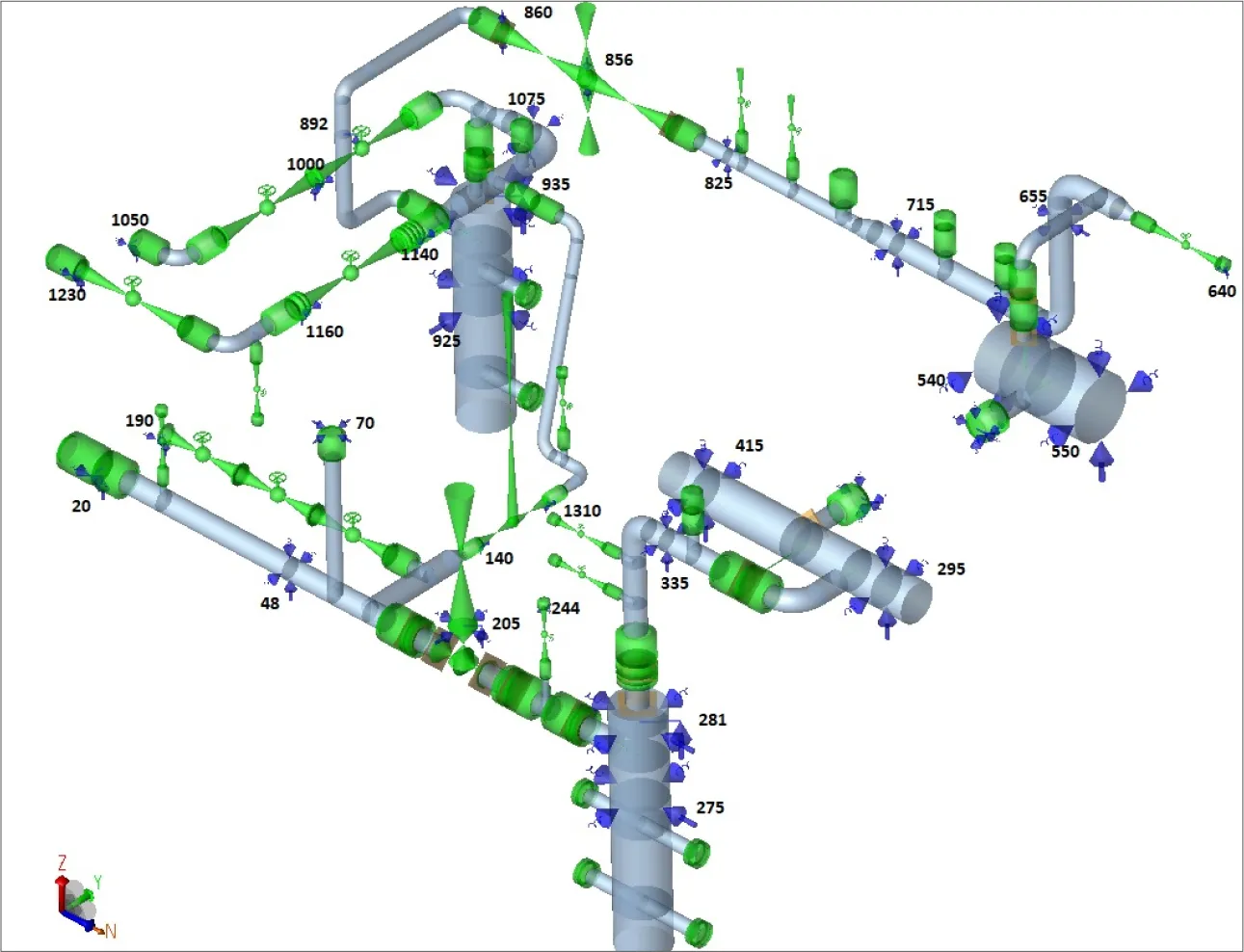

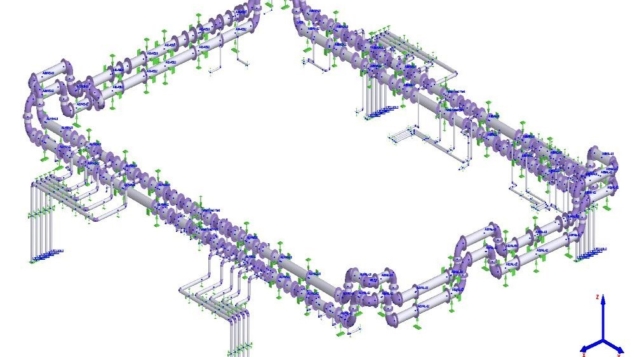

Our focus was simple: piping systems should be reliable, and this is achieved by the proper pipe stress analysis and by assisting the mechanical layout with realistic skid designs. We employed industry standard tools and codes of ASME to analyze the stress limits, load cases, and nozzle loads. With their technical department, our engineering team tried to minimize the delays in meeting the design specs.

Pipe Engineering Solution – Our Process

Our standard procedure of elaborate modelling, load verification, flexibility and layout support was applied here. The engineered piping solution covered 3D model, analysis reports, and stress isometrics. In the case of the skids, we took care of the structural arrangement and the connection points, and it fitted well in their existing plant design.

We matched their internal standards, maintained effective communication, and provided all milestones according to the schedule. Nothing was overcomplicated, and there was concentrated engineering assistance.