- Providing Sustainable Engineering Solutions

- Get a Quote

- Info@fluxiss.com

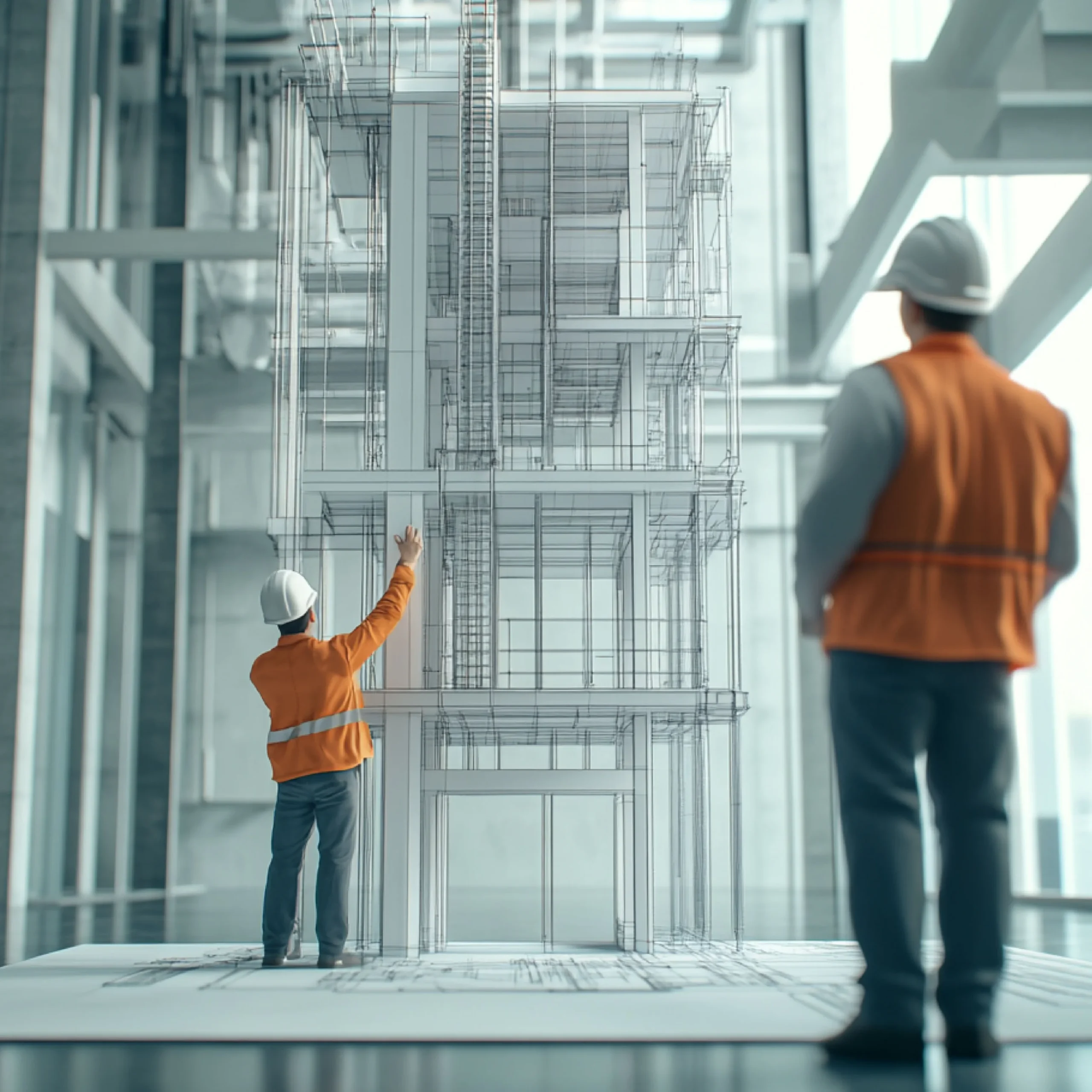

At Fluxiss, we offer a comprehensive range of engineering services designed to meet the complex demands of modern industrial projects. From detailed pipe stress analysis and 3D piping layout to advanced seismic evaluations, our solutions are built on accuracy, compliance, and innovation.

In a professional context, it often happens that corporate clients require pipe stress analysis to ensure reliability.

In a professional context, it often happens that clients demand seismic analysis to evaluate structural safety analysis.

In a professional context, it often happens that clients request 3D piping layouts for accurate system planning.

Civil Engineering Design

Trusted U.S. civil engineering for infrastructure and site plans.

Learn More

Naval Architecture

Trusted Innovative vessel design ensuring stability, safety, and performance.

Learn More

Structural Engineering

Trusted Reliable structural design delivering strength, safety, and compliance.

Learn More

We’re proudly serving clients across the USA, UK, UAE, and Europe. From corporate giants to research labs and the shipping industry,

Pipe Stress Analysis

Accurate pipe stress analysis for safe, code-compliant systems.

Learn More